Inductor Coil Air Coil Air Core Inductor Coil for IC Care System Application

Description

Basic Info

| Insulating Medium | Epoxy Resin |

| Installation | Busbar Type |

| Magnetic Circuit Structure | Single Stage Type |

| Voltage Transformation Principle | Electromagnetic Type |

| Winding Material | 100% Copper |

| Input Voltage | Customized |

| Rated H. V. | Customized |

| Price | Negotiable |

| Efficiency | 70%-95% |

| Quality | 100% Tested |

| Inductor Value | Variable Inductor |

| Power | 15W |

| Frequency | 105 - 205 kHz |

| Temperature | 55 - 65 Centigrade |

| Transport Package | Export Standard Carton with Strong Pallet |

| Specification | customized |

| Trademark | customized |

| Origin | Shenzhen |

| HS Code | 8504500000 |

| Production Capacity | 50000/Month |

Product Description

inductor coil air coil air core inductor coil for IC care system application

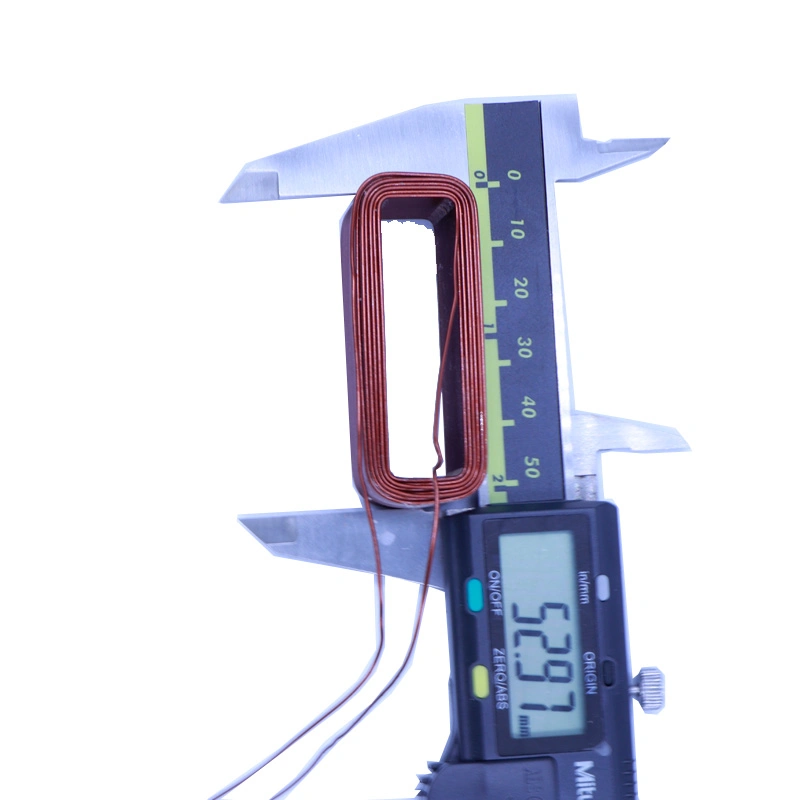

Model | Original China Custom PCB Charger Transmitter Wire Wireless Charger Coil Receiving Induction Qi Transmitter Power Inductor |

| Coil Type | 10 circles, bilayer, unbifilar |

| Inductance | 23UH +- 10% |

| Resistance | 21mΩ |

| Q Value | >70 |

| Coil Dimension | Φ20.5*Φ43*2.4mm |

| Ferrite base | 53*53*2.5 or 50*50*1 or 50*50*2.5mm |

| Test Condition | 100KHZ 1V |

| Notes | Customised lead length accepted |

| Certification | RoHS, Unleaded, SGS, 3C |

Note: Products can be customized according to the wireless charging coil standards or to customer requirements (wire diameter,inner dia.,outer dia.,thickness,inductance,resistence).Wireless charger coil

Specifications

Various structures meet customer specification.

Applications: Fans motor, IC, mobile vibrative motor, touch screen, ect.

Self Bonded Air Coil, Various structures meet customer specification.

Applications:

1. Speaker of Toys

2. IC-Card/ID-Card System

3. Electro-Mechanical displays

4. Antennas and remote control devices

5. Radio Frequency tag Electronic clock

Advantage:

1. Professional engineer

2. Good after-sale service

3. Qualified material and competitive price

4. RoHS certification

5. Small Orders Accepted

6. Ultraminiature size and light weight

Application:

Hearing aids, wireless charger coil, actuator, antenna, RF/ RFID, IC card, car ignition, slot machine, camera, voice, speaker, tracking items, solar consumers, toy, printer machine, car alarm, electronics components, electronic components assembly, motor, monitor system, charger, access control products, miniature plastic injection products.

*All specifications can be customized.

Key Specifications/Special Features:

1. Winding with self-bonding wire

2. Winding different shapes as per your requirement

3. Meet your requirement inductance and resistance

4. Windings are bond by a strong adhesive5. Meeting and compatible with Qi standard of WPC6. More thin and more efficient7. Litz wire winding8. Ni-Mn ferrite material9. For Tx applications working with 12V

10. Power Transfer Efficiency: 75%11. Flexible sheet type is available12. Dimension: 107.95 * 52.5 *4 mm

13. Net Weight: ≥ 5g14. Storage temperature: -20°C- 85°C (-4°F- 185°F)15. Operation temperature: -20°C- 105°C (-4°F- 221°F)16. Output with multi-protection17. Easy to install18. Various structures meet customer specification19. Customized sizes are welcome

Primary Advantage:

1. Professional manufacturer

2. High quality

3. Low price

4. Fast delivery

5. Good after-sale service

6. Qualified material and competative price

7. RoHS, SGS, CE certification8. Small Orders Accepted9. Ultra miniature size and light weight10. OEM/ ODM available

Ther air coil:

About Us

FAQ:

1. Small order quantity workable. From the initial sample design of the spring to the mass production of the springs, we can quickly reach your manufacturing goals and immediately provide the best products because we have an excellent production magement system and expertly trained technical personnel.2. Committed to high quality production. To keep Xuanzhi at the forefront of the industry, we have implemented a stringent internal quality control system and regularly import the latest manufacturing equipment and instruments. Through our precise manufacturing technology and expert mold making process, we provide our customers with the best products and service.3. How to make custom induction coil ? Please provide the specification ,the drawing would be the best .4. What is the leade time for sample? Usually it will takes about 3~5 days.5. What is the lead time for mass production ? Is about 7-10 days, depends on the order quantity.6. Payment term T/T: 30% pre T/T, 70% before delivery.

Our Contact